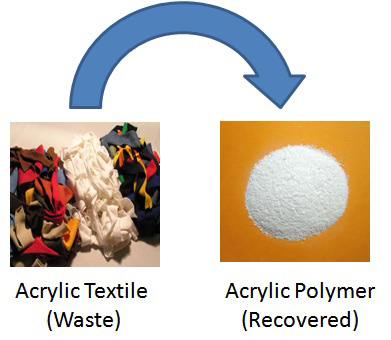

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise. We provide all the necessary technical know-how on ways to remove the colour and recycle the acrylic textile/fibre waste to Polyacrylonitrile, PAN which can be used as the raw material in the Acrylic Fibre manufacturing process. This is process provides a low cost raw material and ensures a competitive edge in the synthetic fibre market.

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise. We provide all the necessary technical know-how on ways to remove the colour and recycle the acrylic textile/fibre waste to Polyacrylonitrile, PAN which can be used as the raw material in the Acrylic Fibre manufacturing process. This is process provides a low cost raw material and ensures a competitive edge in the synthetic fibre market.

Why Textile Recycling!

Textile recycling is for both, environmental and economic benefits. It avoids many polluting and energy intensive processes that are used to make textiles from fresh materials.

- he requirement of landfill space is reduced. Textile waste lead to many problems in landfill. Synthetic fibres don't decompose.

- Pressure on fresh resources is extensively reduced.

- Leads to higher profitability as we use lower cost raw material.

- As fibres get locally available, they don't have to be transported from abroad thus reducing transportation cost and increasing profit.

Majority of textile waste comes from household sources. Average lifetime of any clothing is deemed to be for about 3 years, after which, they are thrown away as old clothes. Sometimes even 'not so worn garments' are also discarded as they become unfashionable, or undesirable. The conventional approach to reuse the acrylic textile waste is manual separation and production of yarn either in the actual form or blending with other fibres.

Our patented technology uses innovative method to remove colour and impurities from the acrylic textile/fibre waste converting them to PAN polymer, a basic raw material for production of grey acrylic fibre. The process uses an environmental friendly approach to minimize the pollution load and maximize the reagents and acrylic polymer recovery. Textile recovery facilities sort out the overly worn or stained clothing into various categories. Some textiles become wiping cloths and polishing cloths. Cotton can be used for making rags or form a component for new high-quality paper. Knitted or woven woollens etc. are "pulled" into the state of fibre for reuse by the textile industry in low-grade applications, such as for car insulation or seat stuffing. Other kinds of fabric are reprocessed into fibres for upholstery, insulation, and even building material

PARTNERS / INVESTORS

Shimi Research Center can provide the technical know-how of the conversion acrylic textile wastes/fibres into PAN polymer and currently looking for partners / investors for scaling up the process from laboratory scales to industrial scale.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...