Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete cracking unit that is environment friendly manner where no lead or other hazardous chemicals is used as a cracking media. The cracked monomer after the purification and distillation would have the purity above 99%. There is no decomposition in the process and the cracked monomer (Light Yellow Color) would have uniform quality.

Acrylic plastic, technically known as PMMA (Poly Methylmethacrylate) offers a number of outstanding characteristics including optical clarity, transparency, and impact and UV stability. The acrylic can be casted, moulded or extruded very easily and provide an attractive replacement for glass. Typical applications include automotive brake lights, medical syringes, sign boards, bathroom fittings, and many more.

Acrylic wastes/scraps, surplus material, cut-offs, damaged inventory are abundantly available for recycling and production of regenerated monomer RMMA (regenerated methyl methacrylate), which can be used as raw material for production of acrylic products.

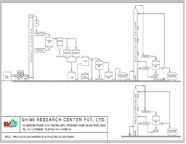

Shimi offers its innovative clean Acrylic Plastic Waste Recycling Cracking Units for recycling different types of acrylic scraps with high yield and low pollution load. The effective cracking technique followed by novel purification method ensures the minimization of monomer loss and high monomer purity.

CRACKING UNITS OFFERED:

Shimi Research Center can provide Cracking Units of the following capacities:

- 1 Tonne per Day

- 3 Tonne per day

- 5 Tonne per day

UPGRADATION AND REFURBISHING OF EXISTING PLANT

If you face any of the following problems in your existing plant, Shimi Research Center Pvt. Ltd. can provide services to eradicate the same:

- Recovery Yield less than 85%

- Purity less than 99%

- Pungent smell in Recovered Monomer

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...