BATTERY BREAKING UNIT

Shimi Research Center Pvt Ltd is a leading Battery Breaking Unit Manufacturer in India. We manufacture advanced Battery Breaking Unit with export quality raw materials. Battery Breaking Units are designed for the treatment of “mixed” batteries. Because of high product quality we are effectively exporting Battery Breaking Units in various parts of the world. At present we are one of the leading exporters of Battery Breaking Units in Middle East and South Africa.

The Battery Breaking Unit is designed for the treatment of “mixed” batteries with external cases in polypropylene and/or ebonite.

The plant is able to treat 5 ton/hr or more of batteries, separating the components in the most efficient way and obtaining high-quality products.

All the equipments are made in SS-304 in order to guarantee long life, good performance and low maintenance costs.

Four products approximately will be generated from the used Lead acid batteries:

- Plastics (8%)

- Separators (7%)

- Metallic (30%)

- Pastes/Lead (55%)

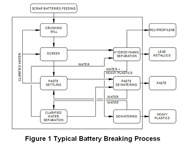

PROCESS DESCRIPTION

It is used Lead acid batteries are received through container / trucks will be unloaded at battery breaking storage area, from where battery will be processed through breaking and separation system.

Scrap batteries are fed to a hammer mill in which the material is crushed to a size suitable for good separation of the components.

The crushed material is classified by a wet screen, which separates the solid parts from the lead paste (lead sulphate and lead oxides) in a stream of recirculating wash water. Separated fines are collected in a settling tank from where the paste is extracted and filtered by a dewatering unit (optional). During screening only a small amount of metallic lead passes into the paste slurry, while oversize grids, poles and other plastic parts are conveyed to the hydrodynamic separator, where the following operations take place:

- Separation of polypropylene in the upper part of the system

- Collection of metallic lead, and extraction by means of a bottom screw conveyor

- Separation of heavy plastics as ebonite, separators, polyethylene, etc.

All these products are conveyed to the relevant collection boxes for further use.

All the water used in the plant is continuously recycled so that, if the electrolyte content of the fed batteries is lower than 10% by weight, the plant does not release any liquid effluent. However, if the electrolyte content increases beyond 10%, then waste water treatment plant would be used to treat the effluent (optional).

Plastics will be on recycle to approved Secondary plastic recycler/ storage. Metallic and Pastes will be consumed in Rotary / Vertical furnaces for smelting. Flow chart of Battery breaking and separation system is as follows:

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...