BAG HOUSE DUST COLLECTOR

Shimi Research Center Pvt Ltd is a leading Bag House Dust Collector Manufacturer in India. We manufacture Bag House Dust Collectors with fine quality raw materials. Bag House Dust Collectors are very effective for removing dusts of various kinds. Because of our eminent product quality we are increasingly exporting Bag House Dust Collectors in various parts of the world. At present we are one of the leading exporters of Bag House Dust Collectors in Middle East and South Africa.

We at shimi research centre specialize in providing you cost effective, simple to operate baghouse dust collectors with a large variety of filters available to suit your needs. Our experts work with you at each step to create and deliver solutions that reap you benefits for a lifetime!

OPERATING PRINCIPLE:

When dust-laden air passes through a fabric, the dust is retained while clean air passes through. The filters are available in envelope, pleated and tubular shapes. The filters are normally suspended from the top and the dust laden air either directed from inside or outside of the filter bags. The cleaning process can be achieved using air pulse jet, reverse flow of air and mechanical shaking mechanism. In all the processes, the dust is collected at the bottom of the system by gravity.

APPLICATIONS:

OUR ADVANTAGE:

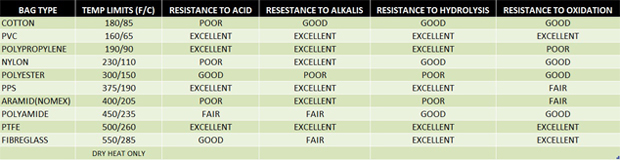

The following is also the list provided to aid the selection of the bag.

In addition to the material type, whether the fabric or material is woven will affect what systems the bag is suitable for

Nonwoven materials consist of randomly placed fibers supported and attached to a woven backing. This strong construction is required for high energy cleaning techniques like pulse jets and aggressive shakers.

Woven materials have fibers wound in uniform, repeating patterns. This construction is used for low energy cleaning methods such as reverse air and lower-intensity shakers. The weave space affects the strength of the fabric and the permeability/capture efficiency of the filter.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

An Ultimate Electrostatic-filter for the extraction and control of oil mist, fumes and dust in the work environment. Shimi Research Center Pvt. Ltd. with its expertise in the field of pollution control equipment introduces the highly efficient, compact, indoor filtering system, IONVENT®, to suit various customer needs.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

A Kitchen scrubber is a smaller and more compact size of the industrial scrubber specifically designed for restaurants and hotels where the volume of pollution is low and limited to particulate matter, oil odor and mist.

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is a leading Centrifugal Blower manufacturer in India. We manufacture Centrifugal Blower with best quality

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Shimi Research Center Pvt Ltd is among the first company in India to develop this kind of Circulation Fans..

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, is a monomer produced on a large scale for the production of poly(methyl methacrylate - PMMA).

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is a leading Supplier of Acrylic Plastic Waste Cracking Unit in India and supply abroad. We provide the complete ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Fibre Recycling Technology/Expertise. We provide all the necessary technical know-how on ...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...

Shimi Research Center Pvt Ltd is the only company in the world till date to provide Acrylic Textile Waste Recycling Technology/Expertise...